日本heiwa精密切割機介紹

日本heiwa精密切割機介紹

High speed precision cutting machine FINE CUT & Precision cutting wheel

For the use of precision cutting wheel, the work piece surface will not be given any damage and given a smoothly cut cross section with speedy cutting, it also reduce time and cost for further processing.

Even tough material is also smoothly and speedy cut, each stage of production control, quality control including traceability are based on high control in order to maintain the high quality production. We also can provide spare parts and prompt maintenance service along the product life.

FINE COOL is the best in lubricity, permeability and cooling performance that prevent clogging of the cutting wheel, extend shelf life of cutting wheel and increase ability to prevent rust growth. Just dilute FINE COOL with 40 times of tap water or dilute NEW FINE COOL with 30 times of tap water before use.

- HOME

- Sitemap

- Privacy Poricy

« Back

印刷する

New advanced machine featuring superior extensibility and operability!

HS-100 G-type

Characteristics

- Oil-less spindle that features an original mechanism that improves stiffness and durability, and which is maintenance free.

- Equipped with a 2.2Kw spindle motor in improving spindle rigidity. Improved cutting capability as vertical cutting using a left steering wheel is supported.

- Utilizes a one touch button instead of a position sensor in the front-rear feed of the work table for positioning and thus faster positioning. Because of this, flat internal base realizes easy cleaning.

- New digital adjustment system used to replace the former volume system provides a more uniform cutting speed.

- Increased stiffness in the front-rear feed operating parts (lead screw) and a stainless front-rear feed cover in preventing any foreign materials entering it.

- Includes a maintenance window in the machine cover for use in adjusting the spindle drive belt, which thereby eliminates having to remove the cover.

- Equipped with a front cover interlock (safety device).

Vise Line Up

| ①Long Vise | SP-V11 |

|---|---|

| ②Surface Rotary Vise | SP-V12 |

| ③Long-type Surface Rotary Vise | SP-V13 |

| ④Double Vise | SP-V14 |

| ⑤Long-type Double Vise | SP-V15 |

* See the available options on pages 12-13 for the lineup of optional accessories and specifications.

NASTON H Series (25 disks/box)

| HS-100G | |

|---|---|

| Standard cutting capacity | ○□pipe 45mm , ●■solid bar 40mm ,■plate 20mm x 75mm |

| Flake cutting | 0.02mm at φ20mm (hard metals) |

| Cutting tolerance | Squareness 0.05mm, parallelism 0.1mm for SK steel φ20mm |

| Work table travel (X, Y) | 110mm with cross feed (manual)?240mm in cutting direction (steering wheel operation) |

| Spindle travel (Z) | 135mm vertically (steering wheel operation), optional specification (max. 250mm) |

| Automatic cutting, Return speeds | 4-300mm/min. 800mm/min. (constant) |

| Diameter of cutting wheel | Standard: φ230mm or φ205mm/φ25.4mm Optional specification: φ255mm/φ31.75mm |

| Diameter of flange | φ110mm (φ90mm: optional accessory) |

| Diameter of spindle, Revolutions per minute | φ25.4mm/3000rpm |

| Spindle motor | AC200 V?3 phase?2P?2.2kW |

| Coolant pump, Tank | AC200 V?3 phase?40 W, 60liters |

| Automatic cutting motor | DC24V?Pulse Motor |

| Dimensions (W x L x H) | 1100 mm x 1170 mm x 1560 mm |

| Machine weight | 500 kg |

| Accessories | Stainless steel standard vise, cleaning water gun, 1 set of cutting wheels for testing, FINECOOL, and 1 set of Paper Filters |

* Please consult the voltage change.

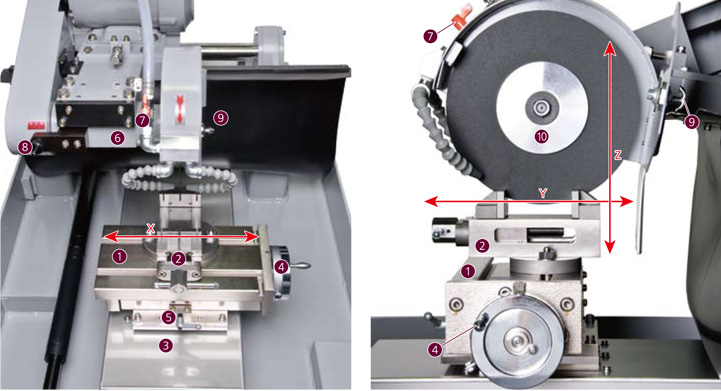

- ① Work table [electro-less nickel plating]

- ② Standard stainless steel vise [jaw opening size 0-80mm]

- ③ Stainless steel front-rear feed cover [contaminant-proof]

- ④ Work table cross-feed steering wheel [with graduated ring]

- ⑤ Work table stopper knob

- ⑥ Oil-less spindle [maintenance free]

- ⑦ Coolant discharge adjustment cock

- ⑧ Spindle stopper for use when changing cutting wheel

- ⑨ Cutting wheel cover open/close knob

- ⑩ Cutting wheel flange [aluminum]

- X Work table travel: 110 cross feed (manual)

- Y Cutting direction travel: 240mm front to rear movement (when operated with steering wheel on right side)

- Z Spindle travel: 135mm vertical movement (when operated with steering wheel on left side)

XYZ Mechanism

Both X-Axis work table travel (left to right movement) and Y-Axis cutting direction travel (front to rear movement) available.

The blade can be vertically adjusted (Z-Axis) as needed using the left steering wheel handle provided at the front of the machine body; this mechanism allows the spindle to move vertically, thereby enabling angled cuts.

Automatic Cutting/Quick-return System

Manually set the cutting position (2mm/rotation) and cutting will automatically start.

The cutting speed can be controlled to be between 4 to 300mm/min depending on conditions such as the material, product shape, and required level of accuracy.

Use of the one-button control to position the cutting stroke fully automates the cutting operation, with the table returning to its original position to complete the cycle.

As long as the machine is first set cutting can take place without an operator.

Options for HS-100 G Type

1. Spindle vertical clearance device

A system in which the blade moves up and down during a quick-return after the cutting has completed.

2. Automatic stepping device

A slice system in which the table travel and cutting direction travel are automatically coordinated.

- * Please contact us for more details on each system.

- * The above systems may not be suitable depending on the shape of the material to be cut.

Document

- FINECUT.Tipe-HS100G.Catalog.pdf(6,258)

« Back

- NASTON GOLD

- NASTON

- FINE CUT

- SP-7

- HS-100G

- HS-45AC

- HS-25/25A

- ACE-20

- 32F-300/500

- 32F-200

- BIRDIEⅡ/S-5

- SS-33/SS-31

- N-7

- LM-P/LM-O

- Options for FINE CUT

![Safety Data Sheet [SDS(MSDS)]](https://www.heiwa-tec.co.jp/english/assets/img//top/bnr_data_sheetEN.jpg)

在線客服

在線客服